Transportation of Dangerous Goods (TDG) - Means of Containment (Road)

On this page

- What is a “means of containment” (MOC)?

- What are examples of small and large MOCs?

- Do overpacks meet the definition for a means of containment (MOC)?

- Can any type of means of containment (MOC) be used for the transportation of dangerous goods?

- What is the purpose of a standardized means of containment (MOC)?

- What is a compliance mark?

- Are there requirements for non-standardized MOCs?

- What is the difference between UN standardized, TC certified, and DOT certified MOCs?

- How do I identify a UN standardized small MOC?

- How do I identify a UN standardized large MOC?

- Can any company manufacture, requalify, retest, or inspect the MOC?

- What are the responsibilities of the consignor, carrier, and consignee with regards to the MOC?

- What are the basic steps for the selection of MOC for road transportation of dangerous goods?

What is a “means of containment” (MOC)?

Back to topThe TDG Act defines a “means of containment” (MOC) as “a container or packaging, or any part of a means of transport that is or can be used to contain goods”.

The TDG Regulations define the following two main types of MOC:

- Small means of containment (Small MOC) whose capacity is 450 L or less

- Large means of containment (Large MOC) whose capacity is more than 450 L

Note: The information below is provided as guidance only. Means of containments (MOCs) are outlined in Part 5 of the TDG Regulations Always check with Transport Canada and the TDG Act and Regulations to ensure compliance.

Please also see the following OSH Answers documents:

Transportation of Dangerous Goods (TDG) - Training (Road)

Transportation of Dangerous Goods (TDG) - 9 Classes

Transportation of Dangerous Goods (TDG) - Classification (Road)

Transportation of Dangerous Goods (TDG) - "Special Case” and “Special Provision” Exemptions (Road)

Transportation of Dangerous Goods (TDG) - Dangerous Goods Marks (Road)

Transportation of Dangerous Goods (TDG) - Reporting Requirements (Road)

Transportation of Dangerous Goods (TDG) - Emergency Response (Road)

Transportation of Dangerous Goods (TDG) - Segregation of Means of Containment (Road)

Transportation of Dangerous Goods (TDG) - Shipping Documents (Road)

What are examples of small and large MOCs?

Back to topExamples of small MOCs include jerricans, drums, cylinders, bags, boxes, combination containers (e.g., packages), composite containers, etc

Figure 1: Small means of containment (MOC)

Examples of large MOCs include Intermediate Bulk Containers (IBCs), highway tankers, and railway tank cars.

Highway tanker

Figure 2: Large means of containment (MOC)

Do overpacks meet the definition for a means of containment (MOC)?

Back to topNo. The TDG Regulations define an “overpack” as “an enclosure that is used by a single consignor to consolidate one or more small means of containment for ease of handling but that is not a minimum required means of containment.” An example of an overpack is a pallet on which small MOCs (e.g., paint cans) are stacked and secured by straps or shrink wrap.

An overpack is never considered to be an MOC - it is an enclosure. Therefore, overpacks are not required to meet any of the MOC requirements of the TDG Regulations.

NOTE: Overpacks for radioactive materials must comply with section 28 of the Packaging and Transport of Nuclear Substances Regulations, 2015.

Can any type of means of containment (MOC) be used for the transportation of dangerous goods?

Back to topNo. Unless there is a special case or provision (exemption), the MOC must meet the specific requirements in Part 5 of the TDG Regulations. Different MOCs are required depending on the quantity , and classification of the dangerous good.

Generally, for an MOC to be exempt from Part 5 of the TDG Regulations, the consignment of the dangerous good must be shipped under a “Special Case” exemption. These types of containers are referred to as non-standardized MOCs. For example, the “Special Case” for “Class 3, Flammable Liquids: General Exemption” specifies the following requirement:

“…small means of containment designed, constructed, filled, closed, secured and maintained so that under normal conditions of transport, including handling, there will be no release of the dangerous goods that could endanger public safety”

What is the purpose of a standardized means of containment (MOC)?

Back to topWhen an MOC is manufactured to a specified standard (as adopted by the TDG Act and regulations), it is referred to as a standardized means of containment (standardized MOC). Standardized MOCs built to a particular standard will bear a “compliance mark”.

Standardized MOCs undergo numerous performance tests such as leak tests, drop tests, stacking test, vibration test, and hydrostatic test. These performance tests depend on the type of dangerous good, and the dangerous good’s classification and packing group. The dangerous good’s packing group sets the requirements for the strength of the MOC (i.e., packaging) which are:

- Packing Group I – Requires the strongest strength

- Packing Group II – Requires moderate strength

- Packing Group III – Requires the least strength

An MOC must also meet other criteria such as compatibility between the dangerous good and the structural material of the MOC, packing or filler material, etc.

To remain in standard, some MOCs must be periodically inspected, tested, and marked at intervals specified by the standard or regulations. These marks describe what, when, and by whom the inspections and tests were performed.

What is a compliance mark?

Back to topA compliance mark is any symbol, device, letter, word, number, or abbreviation that is displayed on a MOC or means of transport to indicate compliance with a safety standard (defined in the TDG Act).

A compliance mark on a MOC indicates:

- that the MOC meets a specific performance level

- the age of the MOC

- whether the MOC has been inspected for integrity

Are there requirements for non-standardized MOCs?

Back to topThe TDG Regulations require both standardized and non-standardized containers to be designed, constructed, filled, closed, secured, and maintained so that under normal conditions of transport, including handling, there will be no release of dangerous goods that could endanger public safety. TDG Regulation cites standards such as CGSB-43.150 (formerTP14850) and CAN/CGSB-43.146 for both standardized and non-standardized MOC.

What is the difference between UN standardized, TC certified, and DOT certified MOCs?

Back to topMost MOC standards in Canada are based on the United Nations (UN) Recommendations. UN standardized MOCs are internationally recognized and can be used anywhere in the world and by any mode of transport. A UN Standardized MOC will display the “UN” marking.

A UN packaging is any bag, box, barrel, drum or jerrican that is marked to indicate that it has met specific performance tests developed by the United Nations Committee of Experts on the Transport of Dangerous Goods. The tests relate to the container’s ability to withstand transportation conditions such as impact, stacking, and internal pressure.

Each packaging is marked with a code that indicates the type of packaging and the Packing Group, which dangerous good form (liquid or solid) can be used, gross weight or relative density, etc.

Some MOC standards are specific to Canada. Cylinders, tubes, highway tanks, some portable tanks are examples of such MOCs. MOCs that are only compliant with Canada’s standards will display “TC” (for Transport Canada) marking. Similarly, MOCs manufactured in the United States will bear the “DOT” (for Department of Transportation) compliance mark.

MOCs manufactured as per other standards (e.g., DOT) are accepted for use in Canada through the reciprocity provisions in Part 5 of the TDG Regulations or in standards referenced in the TDG Regulations. However, exceptions may apply, and reciprocity may not always be permissible.

How do I identify a UN standardized small MOC?

Back to topA UN standardized small container will have a UN marking displayed on its outer surface that meets the marking requirements set out in Sections 2 and 3 and Part I of the following standards:

- CAN/CGSB-43.125 standard for a Type P620 MOC for infectious substances specified in this standard,

- CAN/CGSB-43.145 standard,

- CAN/CGSB-43.146 standard, and

- CGSB-43.150 (former TP14850) standard.

Note: Markings may vary on cylinders or tubes. Please see the Transport Canada document “FAQs on Cylinders and Tubes ” for more information. Please see the Canadian General Standards Board Catalogue to access the standards.

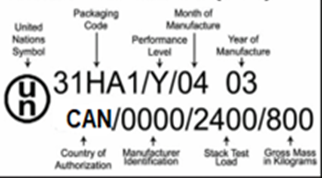

Below is an example of compliance marks for a UN small MOC . Additional markings may be required for some small MOCs. The UN markings are reported in a specific order. They are:

a / b / c / d / e / f /

where

a = The UN symbol

b = The packaging code (e.g., 4GV), and when applicable the letter “V”, “T”, or “W”. See the table below for codes of commonly used packages

c = The package performance level/standard is represented with the capital letters “X”, “Y”, or “Z” followed by the maximum gross mass for solids or specific gravity for liquids

d = The letter “S” for solids or the internal test pressure for liquids

e = The year of manufacture. Plastic drums and jerricans (1H and 3H) must be marked with the month of manufacture.

f = “CAN” Note: Denotes Canada as the country authorizing the use of the UN marking.

g = The name or symbol of the manufacturer

h = The Design Registration Number

Table 1: References for determining UN packing code

| References for determining the UN package code | |||

Type | Material | Category | Performance Level / Standard |

| 1 – Drums 2 – Reserved 3 – Jerricans 4 – Boxes 5 – Bags 6 – Composite packaging | A – Steel B – Aluminum C – Natural Wood D – Plywood F – Reconstituted Wood G – Fibre / fibreboard H – Plastic L – Textile M – Paper N – Metal other than Steel or Aluminum P – Glass Porcelain, Stoneware T – Salvage container V – Special container W – Container manufactured to a different specification that is considered to be equivalent to the standard | A, B, or H Drums – Jerricans 1 – Non-Removable Head 2 – Removable Head A or B Boxes 1 – Ordinary A or B 2 – A or B with liner or coatings C Boxes 1 – Ordinary 2 – With sift proof wall H Boxes 1 – Expanded Plastic 2 – Solid Plastic L Bags 1 – without inner liner or coatings 2 – Sift Proof 3 – Water Resistant M Bags 1 – Multiwall 2 – Multiwall, Water Resistant | X – PG I, II, III Y – PG II, III Z – PG III |

How do I identify a UN standardized large MOC?

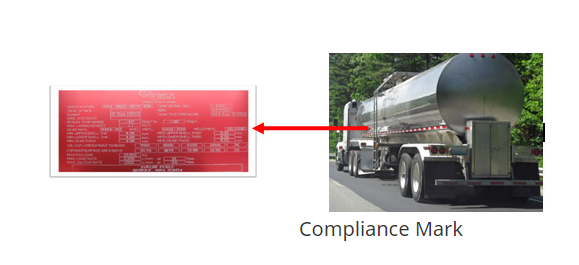

Back to topAll tanks used in the service of transporting dangerous goods must have a plate attached to the shell or an integral part of the structure of the tank. It must be located on the left side of the tank near the front and contain the required information. The plate must be constructed of a metal that will not corrode.

A container's compliance mark conveys important information such as:

- the container type

- the standard to which it was constructed and by whom

- the date it was last requalified and by whom

- limits on how the container can be used

For example, each tank must be marked on the side near the metal identification plate with the following letters, as applicable, to show that the periodic tests have been carried out. The date the tests were carried out will be shown as: Date, Test Type, Last 4 digits of the facility registration number. For example:

02/09 V I K P 1234

shows that in February 2009, visual, internal, leak and pressure tests were carried out. The digits “1234” represent the last four digits in the Transport Canada registration number of the test facility.

NOTE: A new tank requires the initial test information on the manufacturer’s plate only.

Table 2: UN Large MOC test or inspection markings

| Letter | Test or Inspection |

| V | Visual (External) Inspection |

| I | Internal Inspection |

| P | Pressure Test |

| T | Thickness Test |

| L | Lining Inspection |

| K | Leakage Test |

| UC | Upper Coupler Area Inspection |

| WF | Wet Fluorescent Magnetic Particle Inspection |

| C | For TC 341 tanks only if a Cold Vacuum Retention test has been carried out instead of an internal (alternative testing). |

| S | Structural Inspection |

Can any company manufacture, requalify, retest, or inspect the MOC?

Back to topNo. Only facilities registered by Transport Canada can manufacture, assemble, retest or repair TDG containers. Note for some container types the standards require functions like design review or in-plant inspection to be done by persons or agencies registered by Transport Canada.

Transport Canada has compiled a database of registered companies that can manufacture, inspect, test, repair, or design MOCs.

What are the responsibilities of the consignor, carrier, and consignee with regards to the MOC?

Back to topConsignor: When shipping, the consignor or importer is responsible for the selection of the appropriate MOC.

Carrier: Carrier responsibilities for MOCs are not directly specified in Part 5 of the TDG Regulations. However, as a handler of dangerous goods, the carrier should make sure the MOC meets the TDG regulatory requirements. The carrier also should follow their employer’s safe operating procedures for loading dangerous goods.

For example, before loading dangerous goods, the carrier should:

- Check, before loading the dangerous good, the MOC (e.g., tank, cylinders) has the appropriate compliance marks for expiry, requalification, inspection, etc.

- Not take possession of a dangerous good unless it is packaged and labelled according to the TDG Regulations.

- The MOC is not damaged or leaking.

- Make sure the cargo space is suitable for loading. For example, it should be free of nails and other sharp objects.

- Make sure the vehicle is suitable for the dangerous good to be loaded. It must also be in compliance with any applicable Traffic Acts.

- Have a segregation procedure or plan for before and after loading for:

- incompatible dangerous goods

- leaking packages, and

- damaged packages

- Make sure the MOC is loaded securely.

Consignee: Consignee’s responsibilities are not directly specified in Part 5 of the TDG Regulations. However, as a handler of dangerous goods, the consignee should make sure the MOC meets the TDG regulatory requirements. The consignee should have safe operating procedures for receiving shipments that include the following information:

- :

- How to determine the dangerous goods in the shipment are correctly identified, labelled, or placarded and match the dangerous goods descriptions on the shipping paper.

- How to determine the correct shipment of dangerous goods has arrived. For example, workers should be instructed to verify that the dangerous goods descriptions on the shipping paper match the delivered dangerous goods before they accept a shipment of dangerous goods.

- How to inspect the MOC for any damage.

- How to handle damaged or leaking packages. The company should have a policy for damaged or leaking packages. Unless the dangerous good is forbidden to be returned by TDG Regulations or other specific regulations (e.g., nuclear/radioactive substances), the consignee has a right to refuse damaged or leaking packages.

How to segregate or separate dangerous goods when workers are unloading: incompatible dangerous goods - leaking packages

- damaged packages

- What to do when there is an incident (e.g., spill of dangerous goods) involving the dangerous goods at the company’s property.

What are the basic steps for the selection of MOC for road transportation of dangerous goods?

Back to top- Step 1 – Determine the classification for the dangerous good. See the OSH Answers on Transportation of Dangerous Goods (TDG) - Classification. Note the class and packing group of the dangerous good.

- Step 2 – Determine the total amount of dangerous goods to be shipped. The amount to be shipped is used to decide whether you need to select a small or large MOC.

- Step 3 – Check Part 1 of the TDG Regulations to determine if any of the “Special Cases” or non-standardized MOC apply. Note: Even when non-standardized MOCs are allowed, the consignor can elect to use standardized ones as the TDG regulatory requirements are viewed as the minimum requirements needed.

- Step 4 – Check whether there are any Special Provisions listed in Column 5 in Schedule 1 of the TDG Regulations. If any special provisions are listed, next check Schedule 2 to see if the special provision has specified specific allowances or restrictions on the MOC.

- Step 5 - Check Part 5 of the TDG Regulations to determine if there are specific requirements for the dangerous goods to be shipped. Part 5 will outline the standard that must be met by the MOC for the dangerous good’s class. The required standards for the different classes and divisions are also summarized in Transport Canada’s “Dangerous goods MOC” guide.

- NOTE 1: Check existing MOC’s compliance marks before the dangerous good is loaded or packaged.

- NOTE 2: If shipping to a foreign destination, consider any requirements that would apply in the destination country and make sure the selected MOC is compliant with UN packaging requirements.

Step 6 – Select an MOC of an appropriate size as specified in the standard for the dangerous good.

For example: A consignor needs to ship 90 kg of compressed nitrogen gas.

Step 1 - Determine the classification for nitrogen gas.

- Schedule 1 in the TDG Regulations lists the classification as:

“UN1066 Nitrogen, compressed; Class 2.2 SP148”

Step 2 – Small or large MOC

- As the quantity of nitrogen gas is 90 kg it can be shipped in one or more small MOCs. Since nitrogen is a compressed gas it will need to be shipped in cylinders.

Step 3 – Check for available special cases

- Based on the quantity of 90 kg and nitrogen’s Class 2.2, the consignor may be able to ship the consignment under the following special cases provided all the required conditions are met:

- Gross mass of all dangerous goods is 150 kg or less (Section 1.15), as long as the consignor is a retailer

- 500 kg Gross Mass Exemption (Section 1.16)

- Class 2, Gases, in Small MOC Exemption for five small MOC Gross mass – 500 kg or less (Section 1.32.3)

- Note 1: None of the above “special cases” allow for the use of a non-standardized container to be used for Class 2 gases.

- Note 2: Gross mass includes nitrogen mass and the tare (empty) weight of the MOC (i.e., in this case, the cylinder)

Step 4 – Check the special provisions

- Schedule 1 lists special provision 148 for nitrogen gas. This special provision in Schedule 2 does not have any allowances or special requirements for the MOC.

Step 5 – Check Part 5 for a standard

- Part 5 in the TDG Regulations indicates that the MOC for compressed nitrogen gas (Class 2.2) must meet the following standards:

- CSA B340 standard - Contains specifications for cylinders authorized for use in Canada/domestic shipments only or

- CSA B342 standard- Contains specifications for UN cylinders authorized for use in international shipments.

- Also, the cylinder is selected according to the instructions in the most recent CSA B340 standard “Selection and use of cylinders, spheres, tubes”. There are number of possible cylinders for compressed nitrogen gas.

Step 6 – The supplier selects a cylinder based on the vendor’s requirements of size. For example, the supplier can use a cylinder with the following specifications for road transportation in Canada:

- “Transport Canada Specification (TC) -3AAM” (or USA DOT 3AA-2400 equivalent) from the allowed cylinder specifications in the most recent CSA B340 standard “Selection and use of cylinders, spheres, tubes”.

- Schedule 1 in the TDG Regulations lists the classification as:

- Fact sheet first published: 2022-03-31

- Fact sheet last revised: 2022-03-31