Control Banding

On this page

What is control banding?

Back to topControl banding is an assessment method that can be used to manage workplace risks, most commonly from chemical products. It is a process that matches, for example, a control measure (e.g., ventilation, engineering controls, containment, etc.) to a range or "band" of hazards (e.g., skin or eye irritation, very toxic, carcinogenic, etc.). The control banding method also groups chemicals according to similar physical or chemical characteristics, how the chemical will be handled or processed, and what the anticipated exposure is expected to be. The method then determines a set of controls chosen to help prevent harm to workers. Control banding is often used to determine control measures when occupational exposure limits are not set.

In general, bands represent:

- health hazards or risks (e.g., skin or eye irritation, carcinogenic, etc.),

- exposure potentials (e.g., quantity used, or characteristics of the products),

- control measures (e.g., types of ventilation, engineering controls, containment, etc.).

Control banding was originally developed by the pharmaceutical industry as a way to safely work with new chemicals that had little or no toxicity information. These new chemicals were classified into "bands" based on other more-studied materials' toxicity and anticipated safe work practices, taking into consideration exposure assessments. Each band was then aligned with a control scheme. For this reason, control banding is commonly associated with chemical exposures, but similar systems are available for other workplace hazards.

The overall goal of control banding is to help workplaces by providing an "easy to understand" and "easy to apply" approach to controlling hazards. The method is generally meant for small and medium-sized workplaces that have limited expertise in workplace health and safety, industrial hygiene, or chemical control.

Control banding is NOT a replacement for experts in occupational safety and health. Sometimes the control banding advice directly guides employers to seek expert guidance.

How, in general, does control banding work?

Back to topAfter the employer conducts a hazard and risk assessment in the workplace and an uncontrolled chemical hazard is identified, controls must be put in place to protect the health and safety of the workers

Control banding is based on the idea that while there are many chemicals that workers can be exposed to, in practical terms, there are only a limited number of common approaches to hazard control to protect workers. These approaches are grouped into levels based on how much protection the approach offers (with "stringent" controls being the most protective). The greater the potential for harm, the greater the steps needed for control.

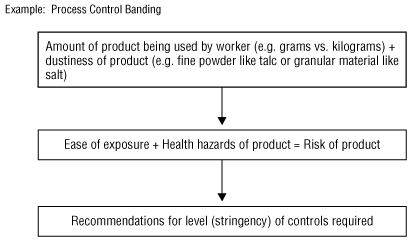

Products are first placed into a "hazard band". Factors used to decide which band a product belongs to include:

- Toxicity of the product (how "poisonous" a product is)

- Ease of exposure (e.g., how easy it is for the product to get into a worker's body such as how fine (dusty) or volatile a product is (how much will enter the air))

- Type of work process being used (e.g., grinding vs. transferring)

- Duration of exposure (amount of time doing the task)

- Quantity of product used in task (small vs. large amounts)

Once the hazard band is determined, a control measure strategy is suggested. A product with greater health hazards and higher exposure potential will need more stringent controls than a product with low health hazards that is unlikely to come in contact with or enter a worker's body.

Adapted from: Control Banding: Pharmaceutical Caterpillar to Mainstream IH Butterfly By Ernest Sullivan, PhD, CIH, ROH, CChem and Om Malik, PhD, CIH, ROH, PEng AIHA Diplomate Article

Note: For more information on hazard versus risk, see the OSH Answers on Hazard and Risk. For more information about controlling risks, see the OSH Answers on the Hierarchy of Controls and Hazard Control.

Is there more than one control banding method?

Back to topYes. Over the years, several control-banding methods have been developed. Examples include the pharmaceutical industry method, a "risk prioritization" method, and the United Kingdom’s Health and Safety Executive’s COSHH Essentials small business method. (COSHH stands for "control of substances hazardous to health".) Note that the COSHH E-tool was discontinued in 2025, although many "direct advice sheets" are available.

Control banding e-tools include:

- International Chemical Control Toolkit from the International Labour Organization

- Control Banding Nanotool (for exposures to nanoparticles) from the Lawrence Livermore National Laboratory

(We have mentioned these organizations as a means of providing a potentially useful referral. You should contact the organization(s) directly for more information about their services. Please note that mention of these organizations does not represent a recommendation or endorsement by CCOHS of these organizations over others of which you may be aware.)

What are some advantages of control banding?

Back to topControl banding offers a way to assess risks and choose relevant control measures to reduce exposures in workplaces. It also allows for control recommendations to be made for products that do not have occupational exposure limits. It is a generic technique to assist workplaces that may lack occupational hygiene expertise in understanding how to manage and control exposure to chemical agents.

What are some limitations of control banding?

Back to topControl banding as a method is not fully validated yet—there is a need for continued testing of control recommendations and the actual exposure to workers. There is no universally adopted (i.e., no single "correct") method of control banding, and each method has limitations. As such, employers should still monitor and evaluate any control measures used in the workplace.

A health and safety professional may need to review recommendations developed by a control banding method to make sure that the control strategy is appropriate, adequately designed, properly installed, and maintained to keep worker exposure within acceptable limits. Monitoring is also required to check that the control methods are working properly.

Not all types of hazards are covered by any one control banding method. It is essential to make sure that the method you are using was created to cover the hazards you wish to control. For example, safe handling of certain chemicals with a specific toxic effect may be covered, but flammability and reactivity hazards may not have been addressed by the control banding system. The recommendation for these types of hazards is to seek expert advice for appropriate control strategies.

Exposure ranges used in the control bands may not be as protective for worker health as an occupational exposure limit that is based on scientific research. The assumptions made about the anticipated health hazards of an unknown chemical can impact the control measures that are provided as solutions. For example, if an unknown chemical is assumed to cause severe health effects to worker health the strictest engineering controls may be recommended. In contrast, an unknown chemical that is assumed to have a medium severity may recommend less strict engineering controls.

There is also some risk in generalizing hazards when using control banding. For example, a product with an annoying odour but low toxicity may need local exhaust for employee comfort, even though the control band may suggest that dilution ventilation would be adequate.

There may also be errors when identifying hazards, such as not having enough toxicity data, incorrect data, incorrect assumptions (e.g., that chemical structural and physical differences within a group mean similar adverse effects) or inaccurate estimation of exposure assessment.

Is occupational exposure banding the same as control banding?

Back to topOccupational exposure banding is a process that has been proposed by the United States' National Institute for Occupational Safety and Health (NIOSH). Occupational exposure banding is intended to be used in situations where information on an occupational exposure limit is not available. The process uses chemical properties and exposure data to categorize chemicals into 1 of 5 bands. It does not provide recommendations, for example, for safe handling and use.

According to NIOSH:

"Occupational exposure banding uses the “banding” concept differently, applying hazard-based data (such as studies on human health effects or toxicology studies) to calculate which of five “bands” is appropriate. Each occupational exposure band (OEB) has an exposure limit range. After completing the OEB process, users must determine whether workplace exposures fall within that range. They must also decide what controls to put in place if the results exceed the range. Once controls are in place, it is important to perform exposure monitoring or assessment to verify the exposures no longer exceed the range of concern."

- Fact sheet last revised: 2025-03-10