Arc Flash

On this page

- What is an arc flash

- What are the hazards related to arc flash?

- What causes an arc flash?

- What elements should be considered when doing an arc flash risk assessment?

- What are some protective measures that can be taken?

- What would be included in preventive maintenance?

- What are approach boundaries?

- How is arc flash personal protective equipment (PPE) chosen?

- What legislation or standards apply to arc flash or electrical safety in the workplace?

What is an arc flash

Back to topArc flash refers to the flash of light and heat that is created when energy is released between a live conductor and another conductor or the ground.

During an arc flash, the energy released heats the air to extreme temperatures such as almost 20 000 °C (35 000 °F). At these high temperatures, items within a metre (3 feet) such as clothing and skin will catch fire, melt, or vaporize. In addition, an arc flash will create an arc blast - the heated air expands suddenly and creates a powerful pressure wave (a blast).

What are the hazards related to arc flash?

Back to topThe heat can cause severe burns which can be fatal. The blast will cause falls and impact injuries. Droplets of melted material and fragments of damaged equipment are spread by the blast at far distances at speeds fast enough for the items to penetrate the body. The pressure wave can also cause damage to hearing or the brain.

What causes an arc flash?

Back to topAn arc flash may be caused by many factors or events, such as:

- Unintentional tool contact with live parts

- A tool dropped on the ground, which creates a spark which starts an arc discharge

- Equipment failure due to poor maintenance or improper design

- Use of tools that spark

- Corrosion of contact surfaces

- Loose contacts

- Worn or damaged insulation

- Dust and condensation on the insulating materials (The dust or moisture provide a path for the electrical current and can lead to flashovers that create an arc discharge)

- Incorrect installation of conductors, such as when conductors of different phases are installed too close

- Incorrect installation of arc-resistant equipment

- Incorrect work procedures.

The possibility of an arc flash increases when there are exposed energized electrical conductors or circuit parts; or when safe work procedures are not followed.

What elements should be considered when doing an arc flash risk assessment?

Back to topAn arc flash risk assessment should be done to:

- identify arc flash hazards

- determine the likelihood of an arc flash, and the injuries it may cause

- determine the severity of the injuries

- determine what protective measures are needed, including personal protective equipment (PPE)

When estimating the likelihood and severity of the event, consider factors such as the design of the electrical equipment, the presence of an overcurrent protective device, and operating time. Also important is the condition of the electrical equipment, and the effectiveness of any maintenance activities.

What are some protective measures that can be taken?

Back to topWhenever possible, do not work on energized equipment. Always follow lockout/tagout procedures as part of a hazardous energy control program.

Other protective measures include:

- Making sure conductors and circuit parts are in a safe working condition

- Using lower energy equipment or current energy limiting devices

- Guarding energized electrical conductors and circuit parts

- Using arc flash approach boundaries, including barricades

- Increasing the working distance

- Using non-contact instruments or procedures, where possible

- Using non-sparking tools

- Implementing work permits, safe work procedures, and job planning

- Posting signs alerting of the hazards

- Wearing shock and arc flash personal protective equipment (PPE)

What would be included in preventive maintenance?

Back to topPreventive maintenance includes:

- Regular inspection for wear and tear of insulation, corrosion, poor connections, overheated electrical conductors, excessive pitting of contacts, or excessive moisture, water, or ice on the equipment.

- Regular measurements of critical components.

- Routine inspections of circuit breakers and relays (develop a testing schedule based on the manufacturer’s instructions or the InterNational Electrical Testing Association (NETA) guidelines).

- Follow established maintenance requirements, including a parts replacement schedule.

- Keep electrical drawings current.

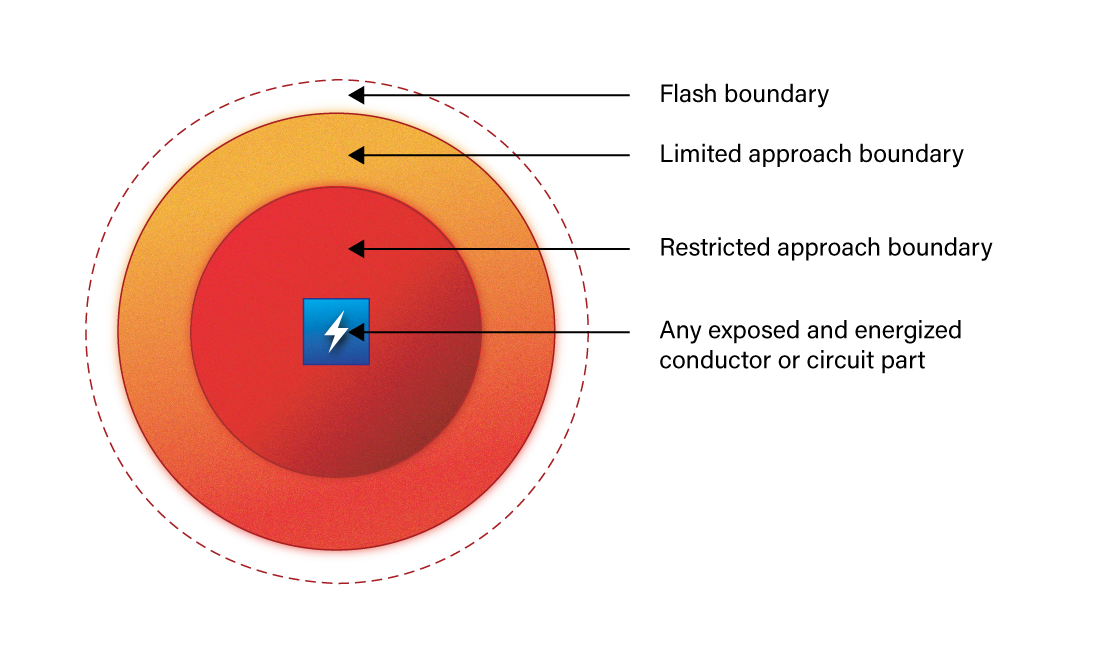

What are approach boundaries?

Back to topBoundaries are used to limit how close workers and others should be to the equipment or circuits, especially when work is being done.

An arc flash boundary is the term used to describe the distance at which a person without personal protective equipment (PPE) may get a second-degree burn if an arc flash occurs. It is assumed that a second-degree burn occurs when the incident energy received by the skin equals 5 J/cm2 (1.2 cal/cm2). A second-degree burn is usually treatable.

There are two types of boundaries that are used:

- Limited approach boundary – the distance from an exposed energized electrical conductor or circuit part a person may approach when a shock hazard exits (i.e., if the person is wearing appropriate PPE and are supervised by a qualified person).

- Restricted approach boundary – the distance from an exposed energized electrical conductor or circuit part a qualified person (only) may approach when there is an increased likelihood of electric shock due to electrical arc over combined with inadvertent movement.

The distance of the boundaries will vary, and depend on:

- the system present (alternating-current or direct-current systems)

- the voltage range (phase to phase) or the nominal potential difference

- the presence of equipment including fuses, relays, circuit breakers, exposed movable conductors or fixed circuit parts

- the use of devices to restrict inadvertent movement

Important to arc flash boundaries is the role of qualified persons. A qualified person is someone who has been trained in and has knowledge about the construction and operation of the equipment or work methods. They must be familiar with appropriate techniques, policies and procedures, work permits, PPE, insulating and shielding materials, insulated tools, test equipment, etc.

For example, unqualified workers should remain a distance away from the exposed energized conductors or circuit parts (including any equipment or objects they may handle). They should not cross into the arc flash boundary unless they are wearing appropriate PPE and are supervised by a qualified person. At no time should an unqualified person enter the restricted approach boundary. Qualified person may enter the restricted space provided any necessary work permits, PPE, tools, equipment, and measures necessary to reduce the likelihood of contact are taken.

How is arc flash personal protective equipment (PPE) chosen?

Back to topWorkers must know how to select, use, and care for the necessary PPE, and understand the limitations of the PPE.

The CSA standard Z462:21 “Workplace Electrical Safety” provides two methods that can be used to determine what type of PPE is required for a specific job:

- The incident energy analysis

- The arc flash PPE category

While either method can be used, only one method should be used at a time when working on the same piece of equipment (not both).

The first method, incident energy analysis, is based on the distance between the worker’s face and chest to the source. It uses the value of the estimated energy of the flash to determine the level of protection that must be provided by the PPE.

The second method, arc flash PPE category method, uses the arc flash risk assessment of the tasks and equipment condition to determine if arc flash-rated PPE is required. Once determined that arc flash PPE is required, one of four PPE categories is selected based on indicators such as minimum working distance, and maximum fault current available and maximum fault clearing time (for AC current) or short-circuit range (for DC current).

In addition to the appropriate clothing and footwear, other PPE items, such as a hard hat (class G or E), face shield, balaclava, hood, safety glasses or goggles, heavy duty leather/arc-rated/rubber insulating gloves, hearing protection, and footwear are required when there is a risk of arc flash incident. All PPE used must be appropriate for energy expected if an arc flash occurs.

What legislation or standards apply to arc flash or electrical safety in the workplace?

Back to topNote that other requirements may be needed that are not discussed in this document. Always consult the legislation that applies in your situation, and with your jurisdiction for complete information. Standards such as the following provide information about establishing a maintenance program and other aspects of electrical safety in the workplace. This list is not complete and other standards may be relevant to your situation or conditions.

- Canadian Standards Association (CSA) Z463 “Maintenance of Electrical systems”

- CSA Z462 “Workplace Electrical Safety”

- National Fire Protection Association (NFPA) 70B “Recommended Practice for Electrical Equipment Maintenance”

- NFPA 70E “Standard for Electrical Safety in the Workplace”

- American National Standards Institute ANSI/NETA MTS “Standard for Maintenance Testing Specifications for Electrical Power Equipment and Systems”

Note: Certain CSA Group standards are available for online viewing. To access these, you must first create an account with “CSA Communities”.

Go to: https://community.csagroup.org/login.jspa?referer=%252Findex.jspa

Once you are logged in, click on the text below the “OHS Standards / View Access” graphic.

Click on the jurisdiction of your choice to see the CSA Standards as referenced in that legislation. Standards may also be purchased from CSA Group: https://store.csagroup.org/

- Fact sheet last revised: 2023-04-11